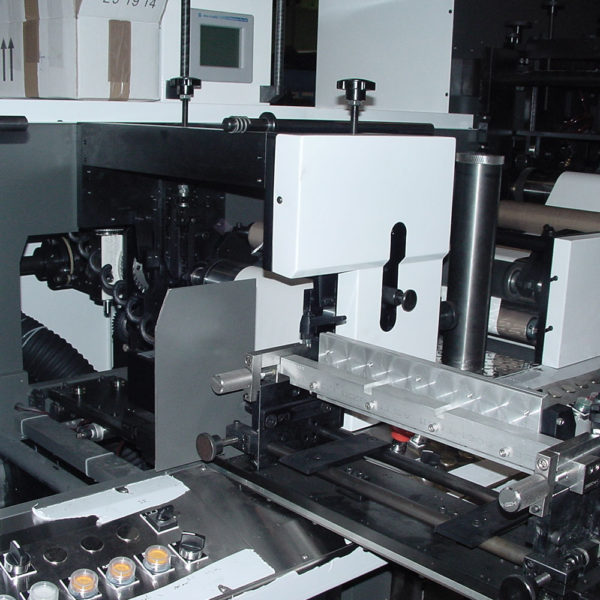

BX Press 13″

The BX Flexible Packaging Press is our most versatile and heavy-duty narrow-web label printing machines. Based on a time-tested platform, this unit can be configured to print on a wide range of substrates, such as self-adhesive labels, plastic sheets and tags of up to 18-point thickness.

The BX press can be configured in two ways:

- Equipped with up to 12 colors, with 360° register high precision gear boxes or single axis servo

- Equipped with with up to 10 colors in the conventional open gear drive assembly.

Features of the BX Flexible Packaging Press include a 42 inch unwinder, lifting system and fully automatic digital electromagnetic unwind brake assembly.

*Please note that we are continually developing and improving our products. As such, all features and specifications on this page are subject to change and the image may not be represent actual product.