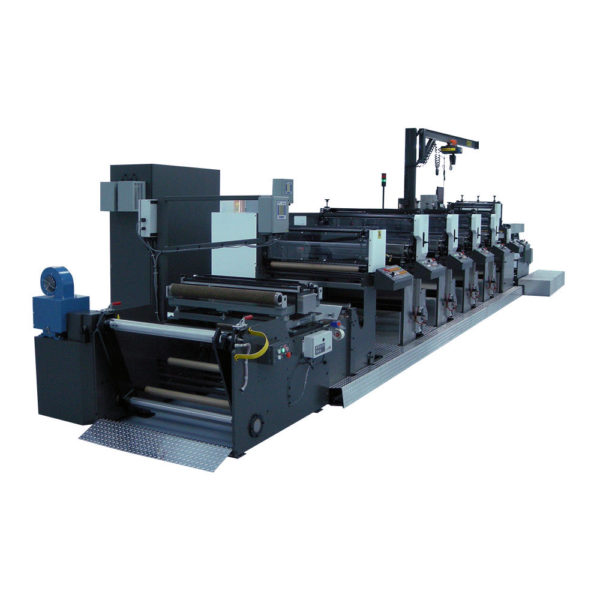

GFXP

GFXP 20″ to 45″

This mid web machine was designed with the operator in mind. Its features include walk through print stations for easy access and adjustment and high speed linear bearings throughout the print station for long lasting repeatability and durability.

The GFXP Mid-Web Inline Flexo Press requires little maintenance and has a proven design that guarantees ease of operation with any film material.

*Please note that we are continually developing and improving our products. As such, the image and information on this page is subject to change.

Get a quote