Rotoworx 330 Digital Finishing

Economic and Modular Digital Finishing

The Rotoworx 330 product range is a state-of-the-art converting and finishing solution designed to transform digitally-printed labels into value-added profitable products. Our basic configuration includes an auto-lifting unwind, semi-rotary die-cutting, lamination unwind, waste matrix rewinder and dual rewind shafts. This platform has a standard web width of 330mm (13 in.) and an operating speed exceeding 200fpm (61m/min) in semi-rotary mode. It’s modular design means it can be fitted with a wide array of different options.

The small footprint and the short web path, in combination with a homing cycle and on/off impression die station, result in minimal waste during job changeovers and roll splices. Re-registration is possible within one or two repeats.

*Please note that we are continually developing and improving our products. As such, the image and information on this page is subject to change.

ADVANTAGES OF THE ROTOWORX 330

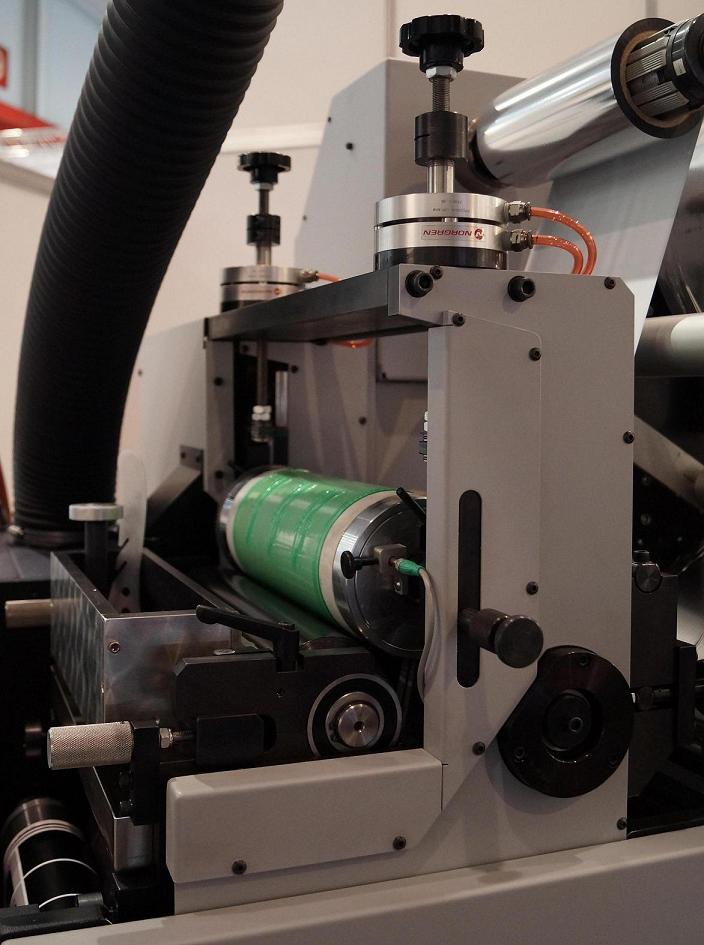

Semi-rotary Die Station

The semi-rotary die-station is complete with sensing technology to electronically re-register to incoming pre-printed material, using a magnetic cylinder and flex tooling for fast changeovers and reduced tooling costs. The die tool anvil system has an off impression mode to reduce waste during changeovers and make ready.

Variable Repeat Flexographic Station

We’ve integrated a flexographic module into the Rotoworx system, in order to provide the versatility and cost-effectiveness of flexography, in conjunction with semi-rotary die-cutting.

Patented ISO-Tensioning System

The system features a field-proven web transport, with high registration accuracy of +/- 180 microns (0.007 in) and a repeat size from 203 mm (8 in) to 559 mm (22 in). Tensioning for each module is controlled independently, which is particularly useful when running sensitive films, difficult matrixes or when through cutting.

Graphics User Interface and Remote Diagnostics

A password-protected user interface, with representations of the machine, facilitates the input of all necessary run parameters and settings. The operating manual, troubleshooting guide and diagnostics are all accessible via this touch screen. The machine can also be run and diagnosed remotely, through a secure internet connection.

Distortion Compensating Software

Rotoworx’s proprietary and user-friendly distortion compensating software aims to cut back expenses associated with re-toll for die-cutting. It maximizes the use of your pre-existing flexible dies by allowing their use on the Rotoworx magnetic cylinder. A full-rotary flexible die purchased for your other presses can thus be placed directly in the Rotoworx and the job manager interface will compensate its distortion requirement.

Tell us what you need

Our experts are available to answer your questions

At Gonderflex, we are committed to increasing your company’s productivity by providing customized flexographic printing and digital finishing solutions, at a competitive price!

For general questions, please fill out this form and our team of specialists will get in touch with you shortly.

We also offer free, no-obligations estimates.